ZIP CURTAIN MACHINES

Lodos Makina combines high efficiency, engineering precision, and technological innovation in zip blind production. The fully automated production systems developed ensure maximum accuracy and continuity in all production stages, including fabric cutting, welding, wick channel application, tube winding, and mechanism assembly. All machines are designed to maintain the tension and structural integrity of the fabric, bringing production standards to international quality norms. With its robust mechanical infrastructure, long-lasting components, and energy-efficient operating system, Lodos Makina represents reliability, technological excellence, and industrial quality in zip blind production.

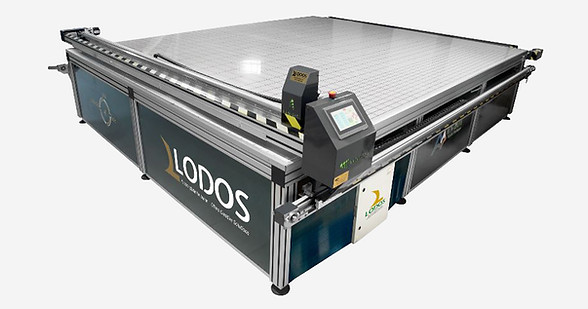

ZIP CURTAIN CUTTING MACHINE

Machine Specifications

The Zip Curtain Cutting Machine is designed to quickly, cleanly, and with repeatable precision cut the fabric used in zip curtain production to the desired dimensions. Thanks to its adjustable cutting and feeding system, it easily adapts to different fabric types and curtain lengths; it standardizes production quality with a smooth cutting line, stable fabric tension, and low waste rate. With its robust mechanical structure, ergonomic design, and low maintenance requirements, it offers a reliable, efficient, and long-lasting cutting solution for zip curtain production lines.

AUTOMATIC WELDING MACHINE

Machine Specifications

The Automatic Welding Machine is designed for high-strength welding of zippers to the side edges of fabric in zip blind production by melting the zipper with heat. It features an operator-controlled feed mechanism that ensures the zipper and fabric are positioned evenly in the welding area, resulting in a clean weld surface, accurate alignment, and repeatable quality. Its flexible mechanical structure, adaptable to different fabric types and zipper sizes, standardizes the zip blind side welding process with a low failure rate and stable production performance. With its robust construction, ergonomic design, and low maintenance requirements, it offers a reliable, efficient, and long-lasting welding solution for production facilities.